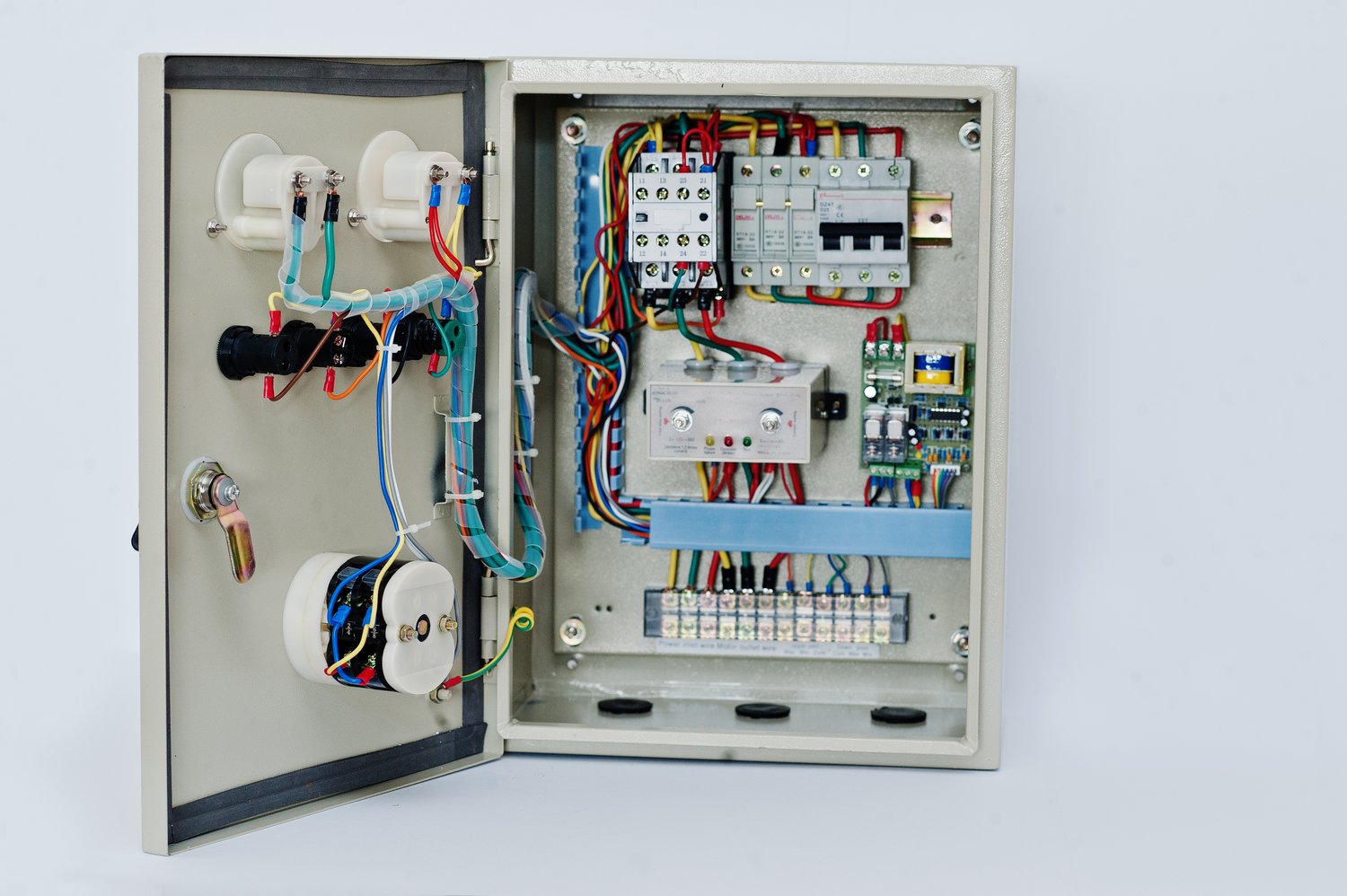

Understanding installation boxes

Installation boxes are crucial components in electrical and plumbing systems. These devices provide a secure housing for electrical connections and plumbing fixtures. They come in various sizes, ranging from 2 inches to 8 inches in diameter. Installation boxes protect wires and pipes from external elements, ensuring safety and longevity. They also facilitate easy access for maintenance and repairs, saving time and effort in the long run.

There are several types of installation boxes available in the market. Each type serves a specific purpose and is designed for different applications. The most common varieties include flush-mounted, surface-mounted, and floor boxes. Choosing the right box depends on factors such as the installation location, required capacity, and local building codes. Proper selection ensures optimal performance and compliance with safety standards.

Installation boxes are typically made from durable materials like PVC, metal, or fiberglass. These materials offer resistance to moisture, heat, and physical impact. PVC boxes are lightweight and cost-effective, making them popular for residential applications. Metal boxes provide superior strength and are often used in industrial settings. Fiberglass boxes offer excellent corrosion resistance, making them suitable for outdoor installations.

When selecting Installation boxes, consider the number of wires or pipes they need to accommodate. The box’s capacity is measured in cubic inches, with standard sizes ranging from 4 to 120 cubic inches. It’s essential to choose a box with adequate space to prevent overcrowding and ensure proper heat dissipation. Always consult local electrical and plumbing codes to determine the minimum box size required for your specific application.

Benefits of flush-mounted boxes

Flush-mounted boxes are designed to be installed within walls, ceilings, or floors. These boxes sit flush with the surface, providing a clean and seamless appearance. They are ideal for new construction projects or major renovations where wiring and plumbing can be easily concealed. Flush-mounted boxes offer superior protection for electrical connections and plumbing fixtures, shielding them from dust, moisture, and physical damage.

One of the main advantages of flush-mounted boxes is their aesthetic appeal. By hiding electrical outlets, switches, and plumbing connections within the wall, they create a sleek and uncluttered look. This feature is particularly desirable in modern interior designs where minimalism is key. Flush-mounted boxes also contribute to a safer environment by reducing trip hazards and preventing accidental contact with exposed wiring or plumbing components.

Installing Flush-mounted boxes requires careful planning and precise cutting of wall materials. The process typically involves creating a hole in the drywall or plaster, securing the box to a stud or joist, and then patching and painting the surrounding area. While this installation method may be more time-consuming, it results in a professional and polished finish that enhances the overall appearance of the space.

Flush-mounted boxes come in various depths to accommodate different wall thicknesses and wiring requirements. Standard depths range from 1.5 inches to 3.5 inches, with adjustable boxes available for non-standard wall depths. When selecting a flush-mounted box, consider the thickness of your wall material and the number of wires or pipes that need to be housed. Always leave enough space for proper wire bending and connections to ensure safe and efficient operation.

Advantages of surface-mounted boxes

Surface-mounted boxes are installed on top of existing walls, ceilings, or floors. These boxes are an excellent choice for retrofitting electrical or plumbing systems in older buildings where cutting into walls is not feasible or desirable. They offer a quick and easy installation process, making them popular for temporary setups or situations where minimal structural changes are preferred. Surface-mounted boxes come in various shapes and sizes to suit different applications and aesthetic preferences.

One of the primary benefits of surface-mounted boxes is their accessibility. Since these boxes are not concealed within walls, they provide easy access for maintenance, repairs, or upgrades. This feature is particularly advantageous in commercial or industrial settings where frequent modifications to electrical or plumbing systems may be necessary. Surface-mounted boxes also allow for greater flexibility in positioning outlets, switches, or plumbing connections, as they are not constrained by the location of wall studs or joists.

Surface-mounted boxes are available in a wide range of materials, including PVC, metal, and weatherproof options. PVC boxes are lightweight and corrosion-resistant, making them suitable for most indoor applications. Metal boxes offer superior durability and are often used in industrial environments or outdoor installations. Weatherproof boxes feature gaskets and sealed entries to protect against moisture and dust, ensuring reliable operation in challenging conditions.

When installing surface-mounted boxes, it’s essential to consider their visual impact on the space. While these boxes are more noticeable than flush-mounted alternatives, many modern designs offer sleek profiles and attractive finishes that can complement various decor styles. Some surface-mounted boxes even feature removable covers or paintable surfaces, allowing for customization to match the surrounding area. Proper placement and careful selection of box style can minimize their visual prominence while maximizing functionality.

Exploring floor boxes for versatile installations

Floor boxes provide a convenient solution for installing electrical outlets, data ports, or plumbing connections in open floor spaces. These versatile devices are commonly used in offices, conference rooms, and retail environments where access to power and data is required away from walls. Floor boxes come in various sizes and configurations, ranging from small single-gang units to large multi-service boxes that can accommodate multiple power, data, and audiovisual connections.

One of the key advantages of floor boxes is their ability to deliver power and connectivity exactly where it’s needed. This feature eliminates the need for unsightly extension cords or exposed wiring, creating a safer and more organized environment. Floor boxes are available in both flush-mount and surface-mount designs, allowing for installation in different floor types, including concrete, raised floors, and wood subfloors. Some models even offer adjustable heights to accommodate various floor coverings.

Floor boxes are designed to withstand the unique challenges of their installation location. Many models feature robust construction with high load-bearing capacities, allowing them to support foot traffic and furniture placement. Additionally, floor boxes often incorporate water-resistant or watertight designs to protect against spills and cleaning solutions. Some high-end models even offer automated pop-up mechanisms or stylish flip-top covers that provide easy access while maintaining a sleek appearance when not in use.

When selecting floor boxes, consider the specific requirements of your application. Factors to evaluate include the number and type of connections needed, the expected load on the box, and the desired aesthetic. It’s also important to ensure compliance with local electrical codes and ADA regulations for accessibility. Proper installation of floor boxes typically involves cutting a hole in the floor, securing the box, and running conduit or cables to the desired location. Professional installation is often recommended to ensure proper fit, function, and safety.

Maintenance and safety considerations

Regular maintenance of installation boxes is crucial for ensuring the safety and longevity of electrical and plumbing systems. Inspect boxes periodically for signs of damage, corrosion, or loose connections. In outdoor or damp locations, check for water ingress and ensure that weatherproof seals remain intact. Clean boxes as needed, removing dust and debris that can accumulate over time. This maintenance helps prevent electrical hazards and ensures optimal performance of connected devices.

Safety should always be a top priority when working with installation boxes. Before performing any maintenance or modifications, turn off the power supply to the affected circuit. Use appropriate personal protective equipment, such as insulated gloves and safety glasses, when handling electrical components. When dealing with plumbing connections, be cautious of potential water damage and use proper tools to avoid leaks. If you’re unsure about any aspect of installation box maintenance or repair, consult a licensed professional.

Proper labeling of installation boxes can greatly enhance safety and facilitate future maintenance. Use clear, durable labels to identify the purpose of each box, the circuits it serves, and any relevant safety information. This practice is particularly important in commercial or industrial settings where multiple systems may be present. Additionally, maintain accurate documentation of your electrical and plumbing systems, including box locations, types, and capacities. This information can be invaluable for troubleshooting and planning future upgrades.

When retrofitting or upgrading existing installation boxes, ensure compatibility with your current systems. Check that new boxes meet or exceed the capacity and safety ratings of the original installations. Consider factors such as wire gauge, amperage requirements, and environmental conditions when selecting replacement boxes. If significant changes are being made to your electrical or plumbing systems, it may be necessary to consult with a professional to ensure compliance with current building codes and safety standards.