Here’s the blog post according to your specifications:

Understanding gas detectors and their importance

Gas detectors play a crucial role in maintaining workplace safety. These devices are designed to identify the presence of harmful gases in the environment. They can detect a wide range of gases, including carbon monoxide, methane, and hydrogen sulfide. In industrial settings, gas detectors are essential for preventing accidents and protecting workers’ health. According to the Occupational Safety and Health Administration (OSHA), proper use of gas detectors can reduce workplace accidents by up to 85%.

Types of gas detectors available in the market

There are two main categories of gas detectors: portable and stationary. Portable gas detectors are handheld devices that can be carried by workers. They are ideal for personal monitoring and spot-checking specific areas. Gas detectors of this type typically weigh between 200 and 500 grams. Stationary gas detectors, on the other hand, are fixed devices installed in specific locations. These units provide continuous monitoring and can cover larger areas. They are often connected to alarm systems for immediate notification in case of gas leaks.

Key features to consider when choosing gas detectors

When selecting gas detectors, several factors should be taken into account. Accuracy is paramount, with most high-quality detectors offering a margin of error of less than 2%. Battery life is another important consideration, especially for portable units. Many modern detectors can operate continuously for up to 24 hours on a single charge. Durability is crucial in industrial environments, so look for devices with high IP ratings. Stationary gas detectors should have at least an IP65 rating for dust and water resistance.

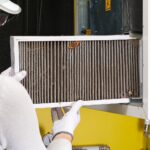

Proper installation and maintenance of gas detection systems

Correct installation is vital for the effectiveness of gas detection systems. Sensors should be placed strategically, considering factors like gas density and potential leak sources. Regular maintenance is essential to ensure reliable performance. This includes calibration, which should be done at least every 6 months. Sensor replacement is typically required every 2-3 years, depending on the specific model and usage conditions. Proper training for all employees on the use and interpretation of gas detector readings is also crucial for workplace safety.

- Conduct weekly visual inspections of all gas detectors

- Perform monthly bump tests to verify sensor response

- Keep detailed records of all maintenance activities